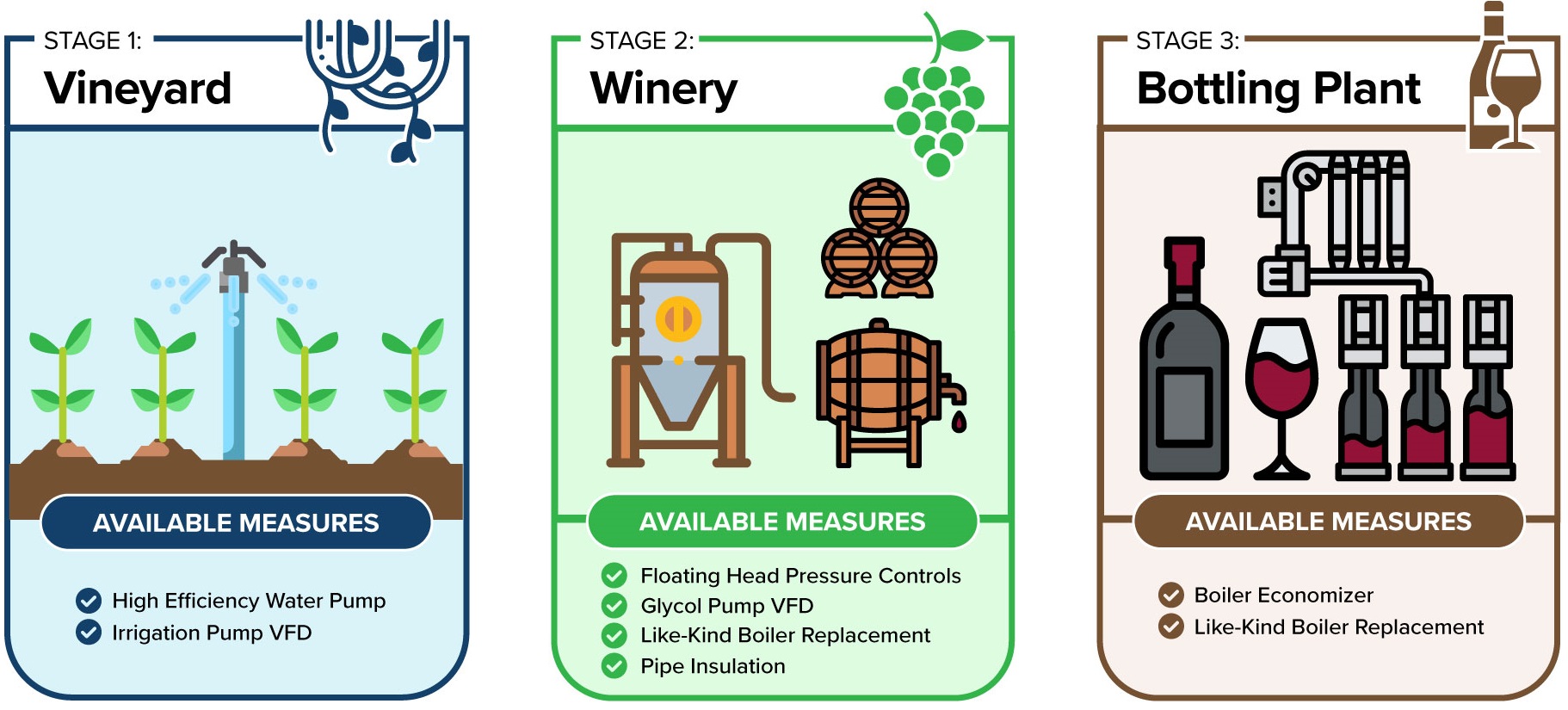

Grape to Bottle: Energy efficiency rebates for vineyards and wineries at the bottling plant

Producing wine consumes a lot of energy and water. From irrigating the vineyard and harvesting grapes, to bottling and treating wastewater—there are unique opportunities for agriculture business owners to lower utility bills and increase profit margins.

The Agriculture Energy Saving Action Plan (AESAP) offers cash rebates and financial incentives at every stage of the winemaking production process to help you improve operations and lower costs. Thinking holistically about energy efficiency across your winemaking operation will maximize your rebate opportunities and long-term energy savings.

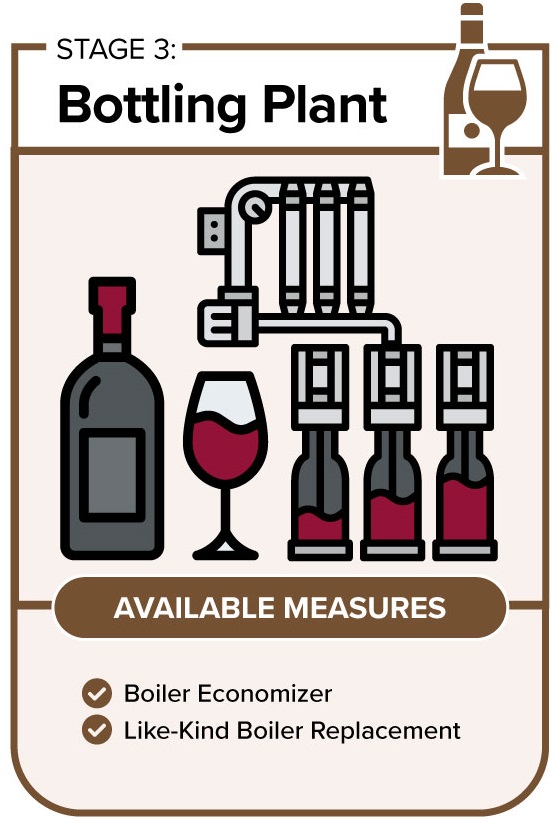

At the Bottling Plant

Rebates on boiler replacement and boiler economizers

When it comes to optimizing your boiler operations for your bottling facility, there are two key options: installing a boiler economizer and boiler replacement.

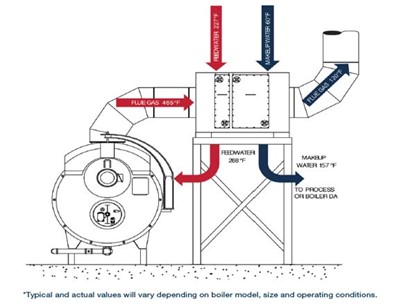

Utilizing recovered heat improves boiler efficiency and often reduces fuel requirements by 5% to 10%. Fuel savings resulting from boiler economizers can produce a rapid return on investment while reducing the release of greenhouse gases. AESAP provides rebates for installing qualifying steam boiler economizers.

Figure 1: Typical two-stage heat recovery system. Learn more: https://www.caetrm.com/measure/SWPR007/01/

Custom energy projects: savings beyond energy rebates for your winemaking business

Mid-sized and larger wineries can also benefit from customized, calculated incentives. AESAP helps ensure your winery can achieve optimal efficiency, no matter what you need to upgrade. Customized incentives are determined by the amount of energy saved and are tailored to meet the specific needs of your business. AESAP provides project support and engineering services at no cost to quantify energy savings and offers an incentive value for the energy-saving measure.

Winery projects that may qualify include projects like improving aerator efficiency for wastewater treatment, replacing metal halide or linear fluorescent lights with energy-efficient LEDs, compressed air upgrades and refrigeration improvements—including installing efficient compressors, condensers, chillers and advanced controls. Advanced VFD upgrades can also qualify. For example, a large winery recently installed a 450-HP VFD on a new screw compressor in an ammonia refrigeration plant. They’re set to receive an incentive of about $17,000, and the project is estimated to save the business $12,000 annually in energy costs.

Learn how to lower energy costs and save water at your winery

Reduce operating expenses and increase profit margins without impacting the quality of your wine with help from AESAP. View our incentives page to see the rebate levels and refer to the Rebate Catalog for equipment specifications on these and all available AESAP rebate opportunities. In addition to rebates, larger projects might be eligible for no-interest on-bill financing. AESAP can also connect you with a trade ally who can help you start your energy-saving project.

Have specific questions about your business? Get in touch today!

Posted January 19th, 2023